|

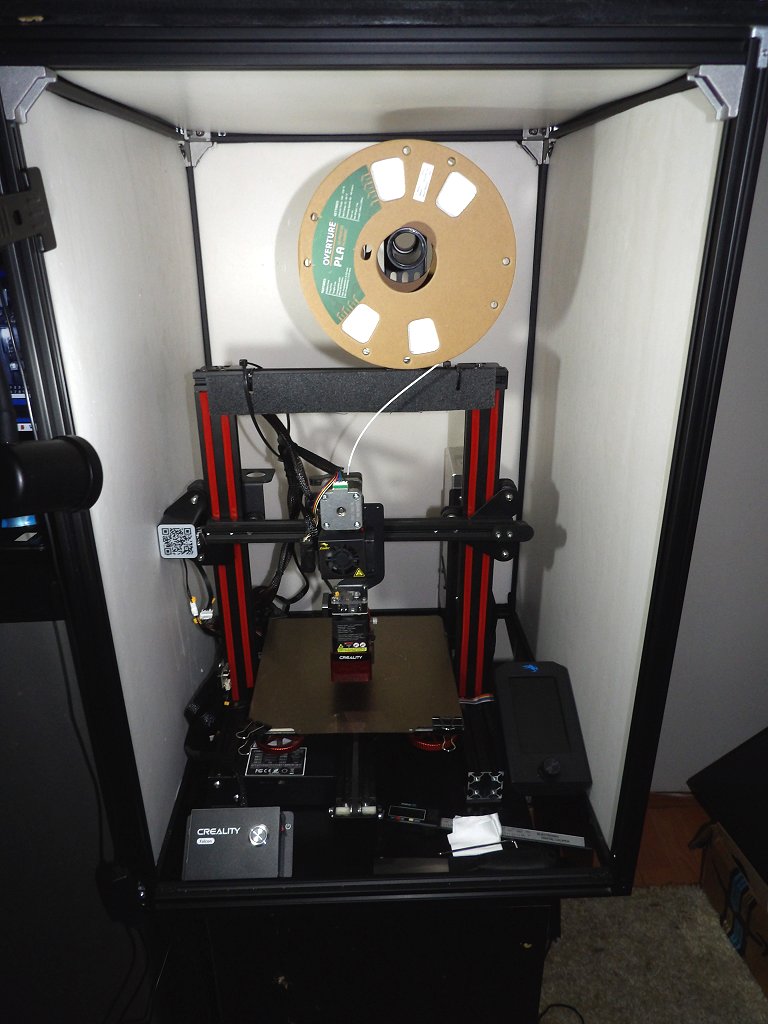

| I hesitated getting into the 3D printer world not having any real need to the technology it offered. That changed when a few projects I planned needed specialty components that I could not purchase. I purchased a Creality Ender 3 3D printer.about 2 years ago. I looked at several brands and went with the Creality. It was inexpensive starter printer that would meet my needs for occasional printing. I ran into the usual problems that a 3D printer sees. Keeping the bed leveled, filament not sticking to the bed and finding the right temperatures for the head and bed. I changed the head to a direct filament feed, added a second Z axis drive and changing the bed springs to see if that would help. To some degree it did but did not solve the filament sticking issue. I put printer aside for a while while working on other projects. A couple of months ago I decided to take another look at the issues. Doing a bit of research I tried several bed plates. some worked better than others but did not keep the first several layers from warping. I decided to upgrade the controller board to the latest version and a new display, The upgraded operating system provided more control options that made the printer more reliable and consistent. Two new features that I had available that I found to be most useful: Filament Control and Mesh Mapping. The filament control provides loading, unloading and purge features. The main feature that solved most of my bed warping was the mesh mapping. With this feature the head is moved and with a CR Touch probe along a grid. It creates a map relative to the center of the bed. The screen displays how much each grid differs from the center with a color coded display. Adjustments can then be made to the bed at each corner. The mesh can be saved so when printing the Z depth is automatically adjusted to keep the extruder at the same level off the bed. Along with use of a metal PEI plate my printer is more reliable and consistently prints with out issues. I feel more comfortable taking on projects that I couldn't do before. Using T Slot 2020 Aluminum Extrusions I constructed enclosures for each unit. I wanted modular units so I could set them up when I needed them. Because of lack of table space they were designed to be stackable. |

|

|

|

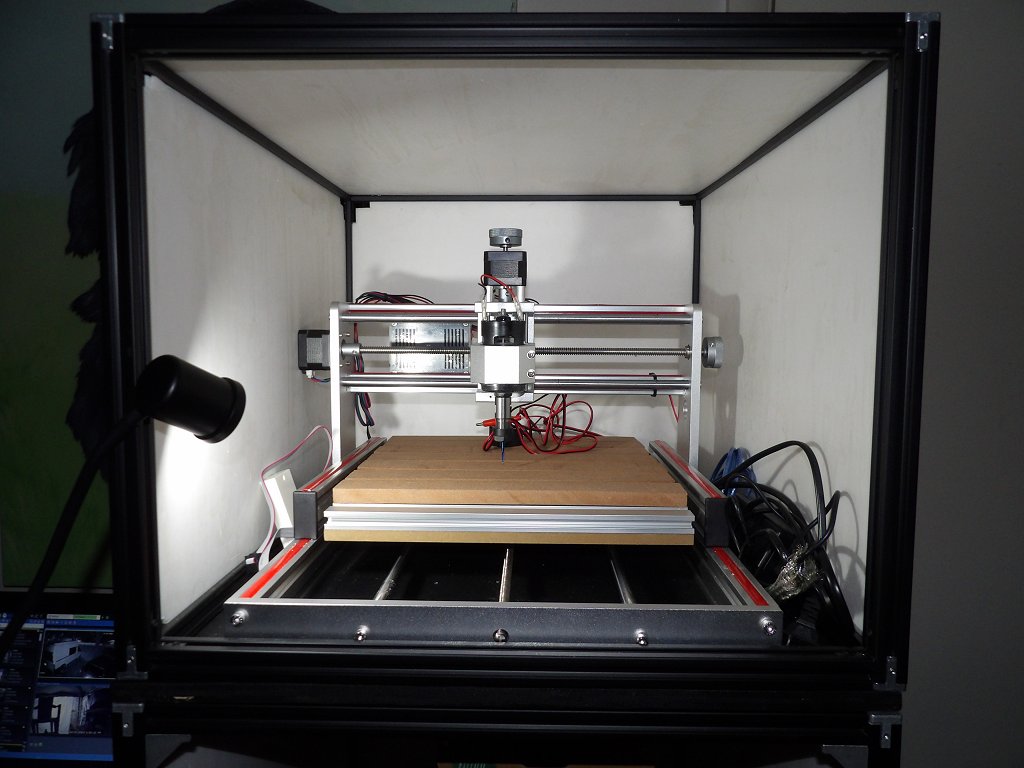

I recently purchased a table top CNC 3018 Pro Engraving Machine. I have other projects planned and a table top CNC would be useful. After assembling and testing I decided to expand the bed. The one I purchased did not have an exact kit so I purchased one that was close to my model. I had to make some changes to bolts and modifications to the extended be kit to make it work. I did end up with a CNC that went from a 7" x 14" to a 14" x 14" bed.

|

|

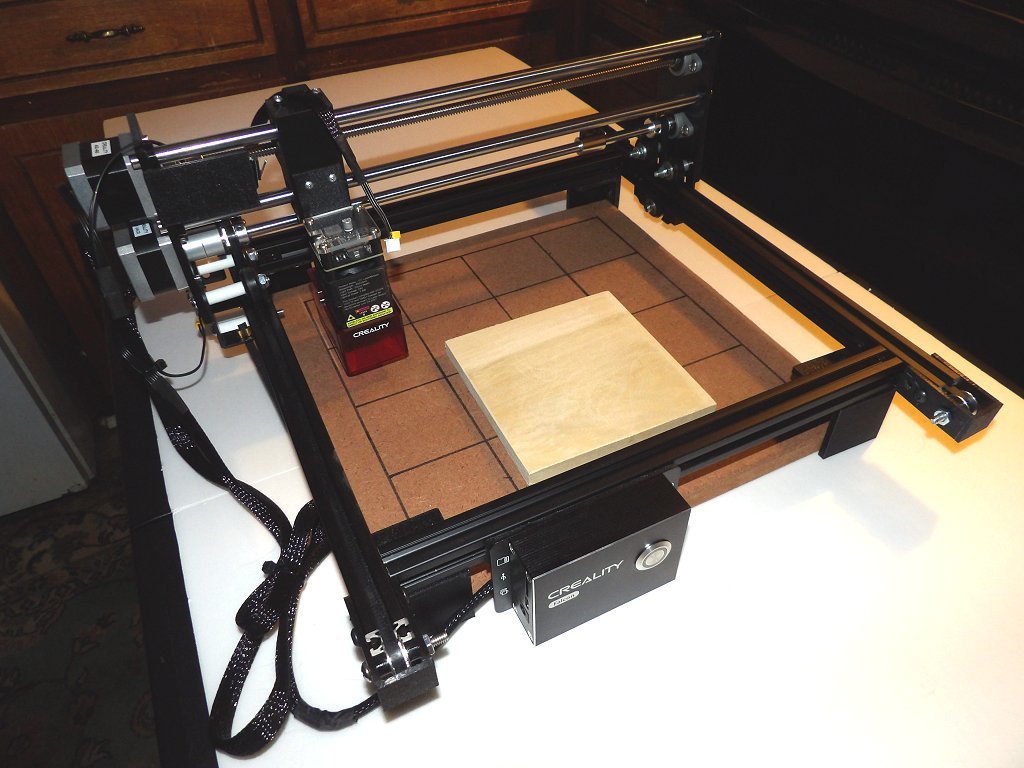

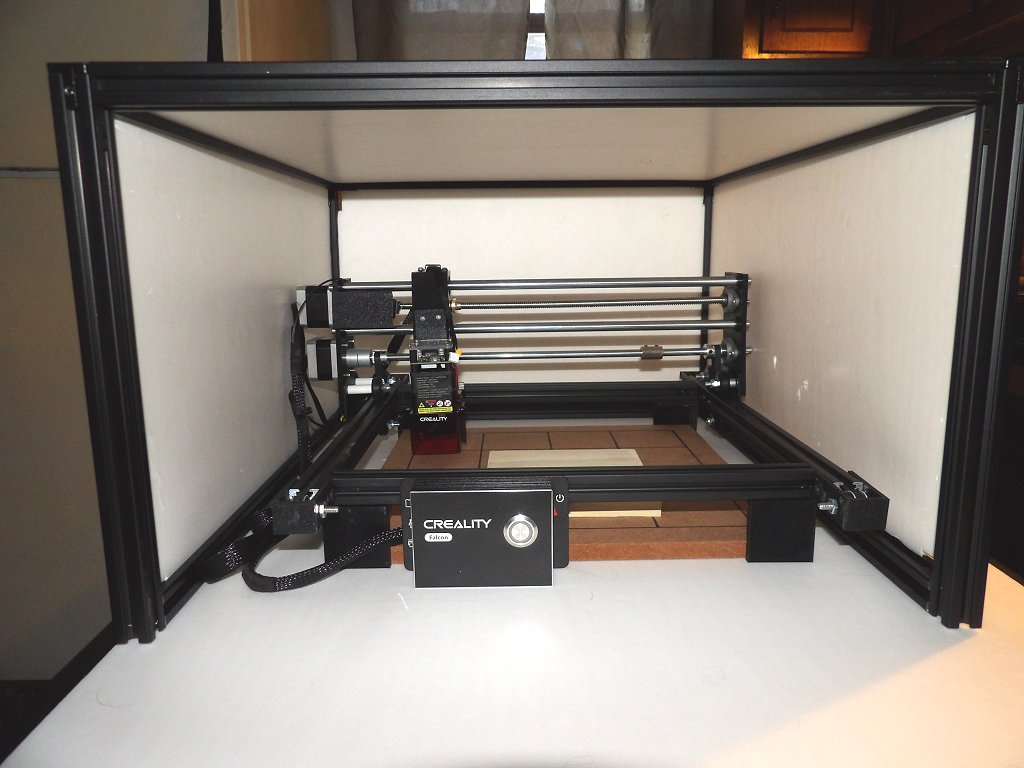

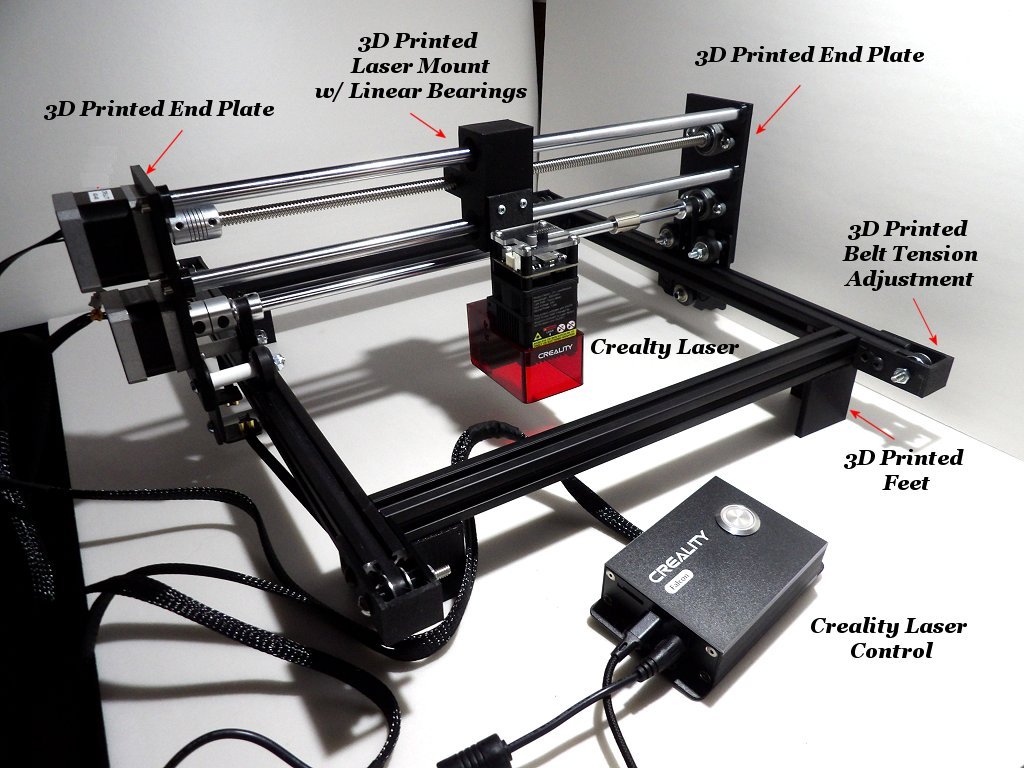

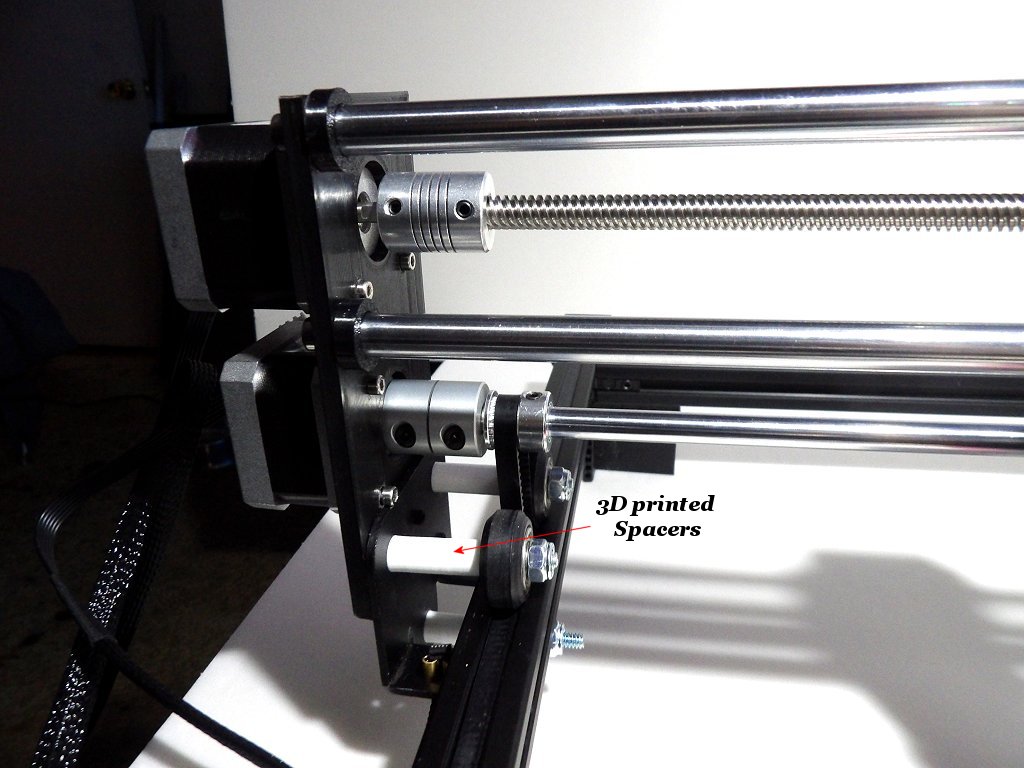

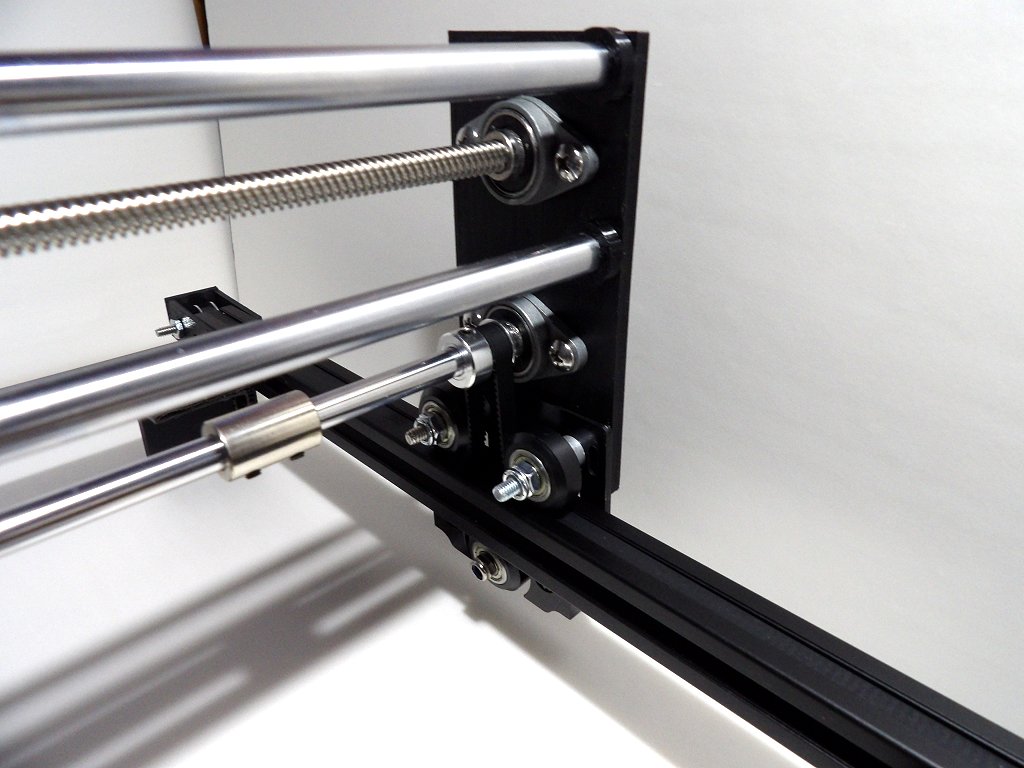

To complete the tools for my various projects I purchased a Creality Laser accessory. To add it it to the printer the x and y stepper motors and their limit switches on the printer had to be unplugged and replaced with the lasers cables. That would be inconvenient if swapping between printing and engraving in a short amount of time.

Looking at the hardware I have in my unused parts boxes I found that I could build a stand alone laser framework with a few more purchases. I could buy one but price and size were an issue. I needed a small table top unit about the same footprint of the CNC and printer. Now that I a very reliable 3D printer I was able to manufacture the parts I need to make a custom unit. The x and y limit switch positions were dictated by Creality from the 3D printer location. I have an order for some screw in nut threaded wood inserts for the base plate. This will allow for the clamps to securely hold the wood or metal in place. Other than the screw nuts the laser unit is completed.

|

|

|

|

|

|

|

|

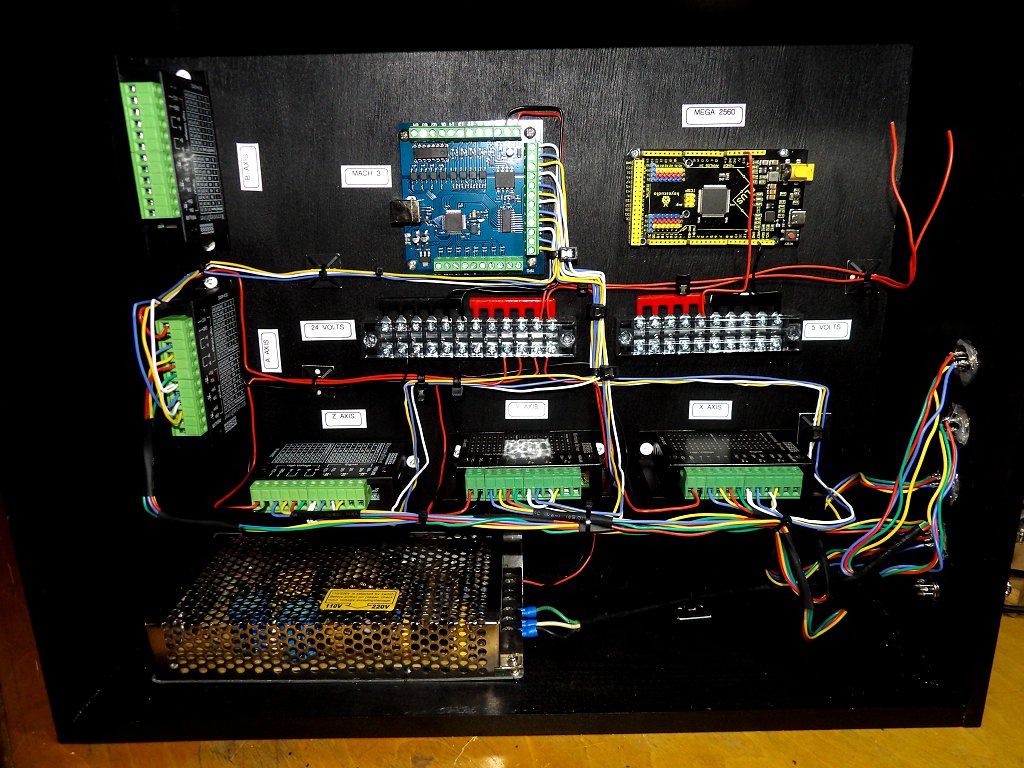

Latest project for future CNC/Milling Machine

|

|

|

Website including images displayed on this website are the property of John R. Havrilla, Chapel Hill, NC and are protected under United States Copyright Law. Any use without the express authorization of John R Havrilla is expressly forbidden. Violators will be prosecuted to the full extend of the law. |